The Art of Firearm Manufacturing at Amol Firearms

Amol

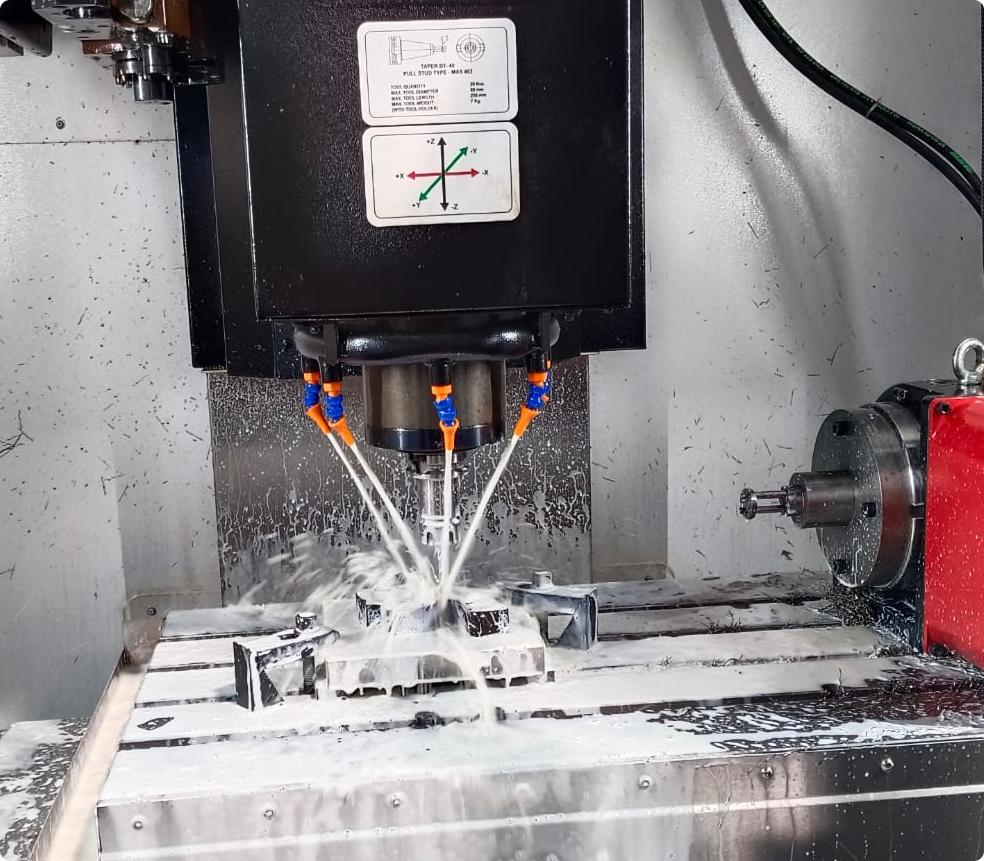

At Amol Firearms, we believe that the perfect firearm is a combination of cutting-edge technology, high-quality materials, and precision craftsmanship. Our manufacturing process is meticulously designed to ensure durability, reliability, and superior performance. This page provides an in-depth look at how our firearms are created from raw materials to final distribution.